Delivery route planning software requires a broad range of features and technologies in order to effectively lower costs and boost #supplychain efficiency.

Choosing delivery planning software is not as easy as you might think. Route optimization calculations are hard. Really hard. Expensive too. Many delivery planning and route optimization companies take algorithmic shortcuts to lower their costs (relying on the fact that it is almost impossible to determine the optimal solution just by looking).

Here are the 5 top delivery planning features to look out for when choosing a route optimization app or API.

- Cost-Based Route Optimizations

- No Algorithmic Shortcuts

- Accurate Vehicle Capacities

- Flexible Location Constraints

- Shareable Delivery Plans

1. Cost-Based Route Optimizations

Modern companies operate diverse fleets with many different vehicle types. These not only have differing carrying capacities, they also have different associated costs per distance. A van is less fuel efficient than a scooter. A truck driver may command a higher per hour wage than a light vehicle driver.

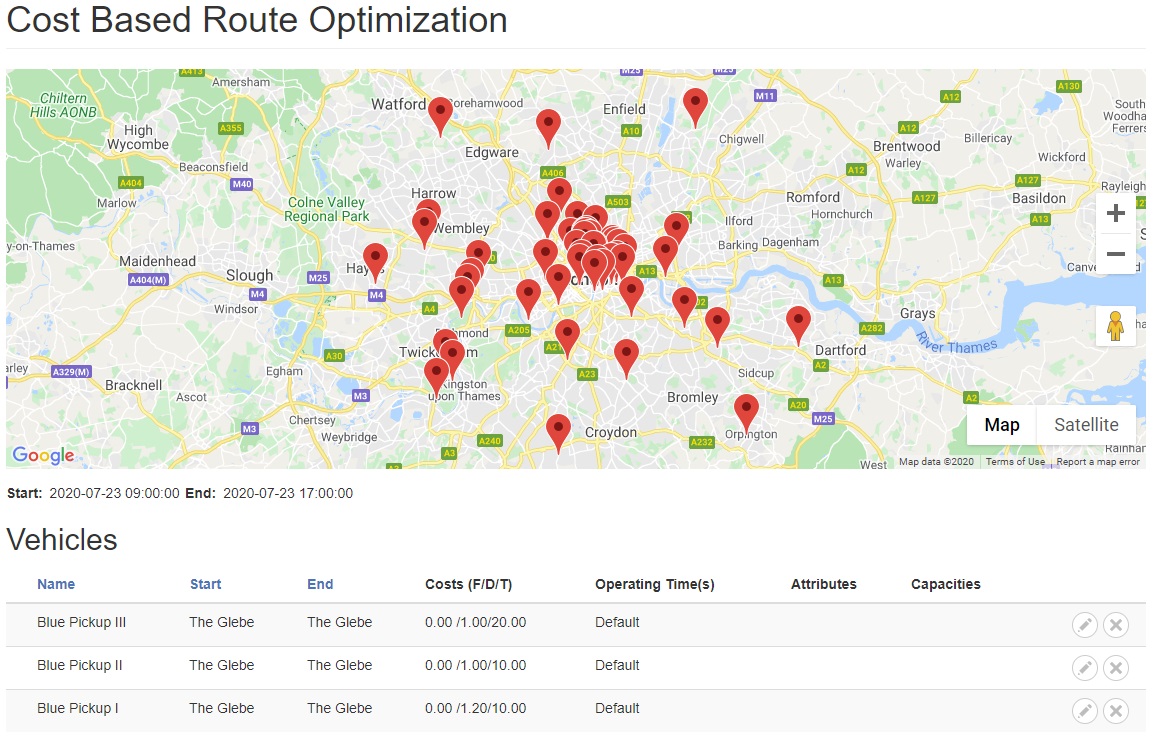

Consider the following delivery schedule of 3 vehicles and 50 locations that needs to be optimized for same day deliveries.

Costs are denoted by F/D/T (Fixed, Distance & Time). There are two salient points here:

- Blue Pickup I incurs a distance based cost of $1.20 - as opposed to the two other vehicles that only cost $1 per km

- Blue Pickup III incurs twice the per-hour time based cost of $20 as the other vehicles

To mimic delivery planning software that only considers distance costs, you would set the time costs for each vehicle to $0, meaning that time does not contribute to the overall cost of the system (something that obviously doesn’t apply to delivery companies in the real world). The same limitation applies to time-based only optimization platforms.

What would cause these differences in operating costs? Perhaps one vehicle requires a driver and a partner to help unload heavy deliveries. Perhaps one vehicle is slightly older and is no longer as fuel efficient. It doesn't matter. In the real world, different vehicles in the fleet have different cost profiles and these need to be considered in any delivery planning calculation to best lower the overall cost to company.

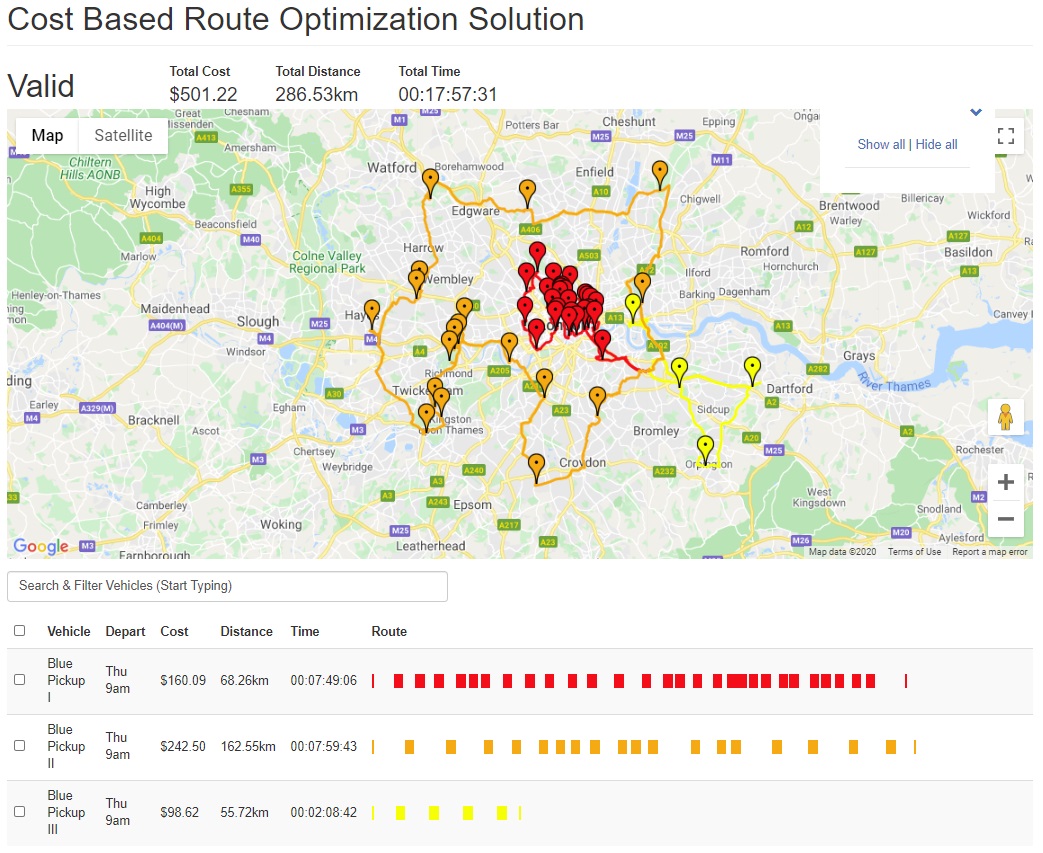

The resulting delivery schedule is pretty interesting, and possibly not what you might expect at first glance.

Blue Pickup I actually spends a long time making deliveries. In fact only about 10 minutes shy of the 8 hours allotted by the schedule constraints - almost the same amount of time spent by the cheapest vehicle, Blue Pickup II.

However, look closely at the amount of distance each one travels. Blue Pickup I travels a smidgen over 68km, while Blue Pickup II had to travel more than twice that at just over 162km. That's a difference of nearly 100km.

At the same time, Blue Pickup III spent a fraction of the allotted time on the road to keep its high time-based cost from driving up the overall cost of the fleet.

This highlights the difference between hypothetical delivery planning and route optimizations that don't cater for the complex interplay between real-world time and distance based costs.

2. No Algorithmic Shortcuts

Consider a very small delivery company consisting of a single vehicle. It has to deliver packages to 50 locations on Monday. Working out how many possibilities there are is given by:

That's a lot of possibilities for a computer to check. Let's state this another way for perspective.

In the real world, companies tend to operate fleets of vehicles. By the time you attempt to tackle these problems the numbers become so astronomical as to be meaningless to humans. Consider the example of a small delivery company operating 5 vehicles with 100 locations to visit in a single day. The calculations for this problem are given by:

where V is the number of vehicles (5) and L is the number of locations (100). Plugging in these numbers gives us:

That number is so big we really need to wonder how long it would take a really fast computer to check each permutation in order to find the optimal route.

I'll spare you the tedious calculations (you can find them at Route Optimization Explained). Suffice to say it would take all the supercomputers we've ever built all the time remaining left in the Universe, again, and again, and again...

A favorite trick of route optimization and delivery planning software designers is to take a shortcut to reduce the complexity to manageable levels. They simply divide up the map into roughly equal quadrants and send vehicles to each one. This reduces redundancy in the routes vehicles take. They don't tend to overlap and travel back and forth on the same roads unnecessarily.

The downside is that, more often than not, in the real world, more optimal solution don't look like this. It's possible to find more efficient routes by using better algorithms with more expensive calculations. It make things more complex and expensive behind the scenes, but shaving off even a few percent can save millions of dollars in the long run.

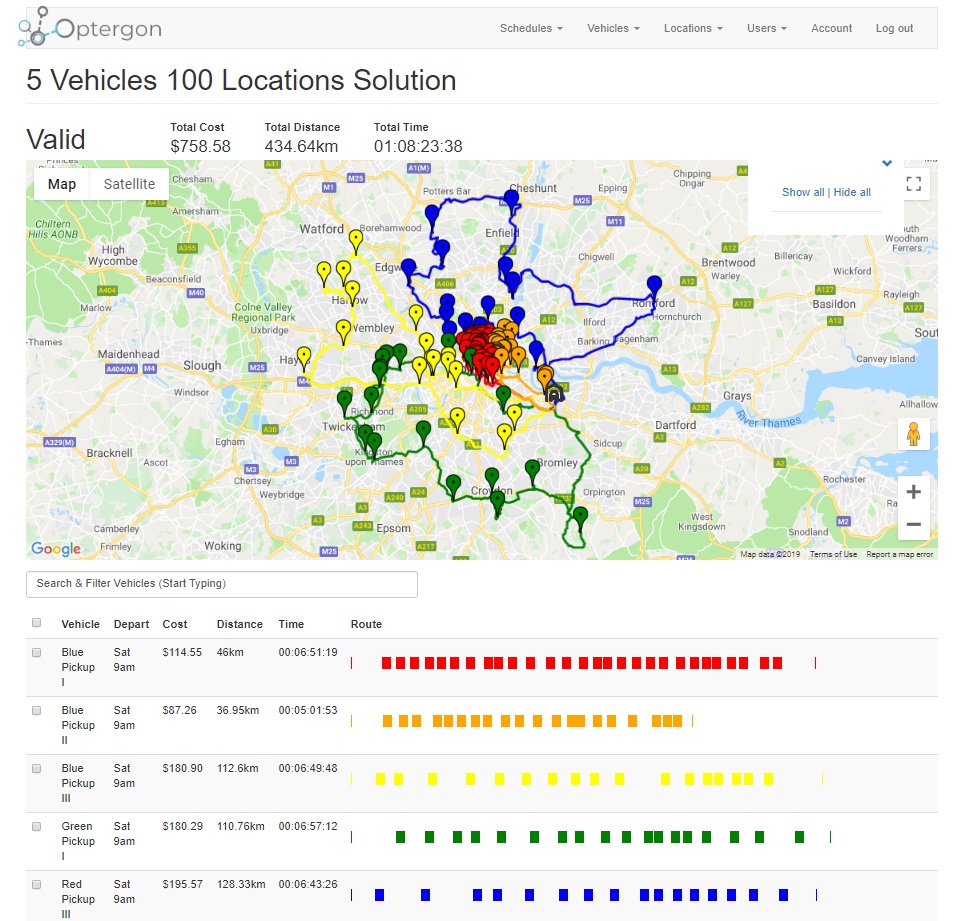

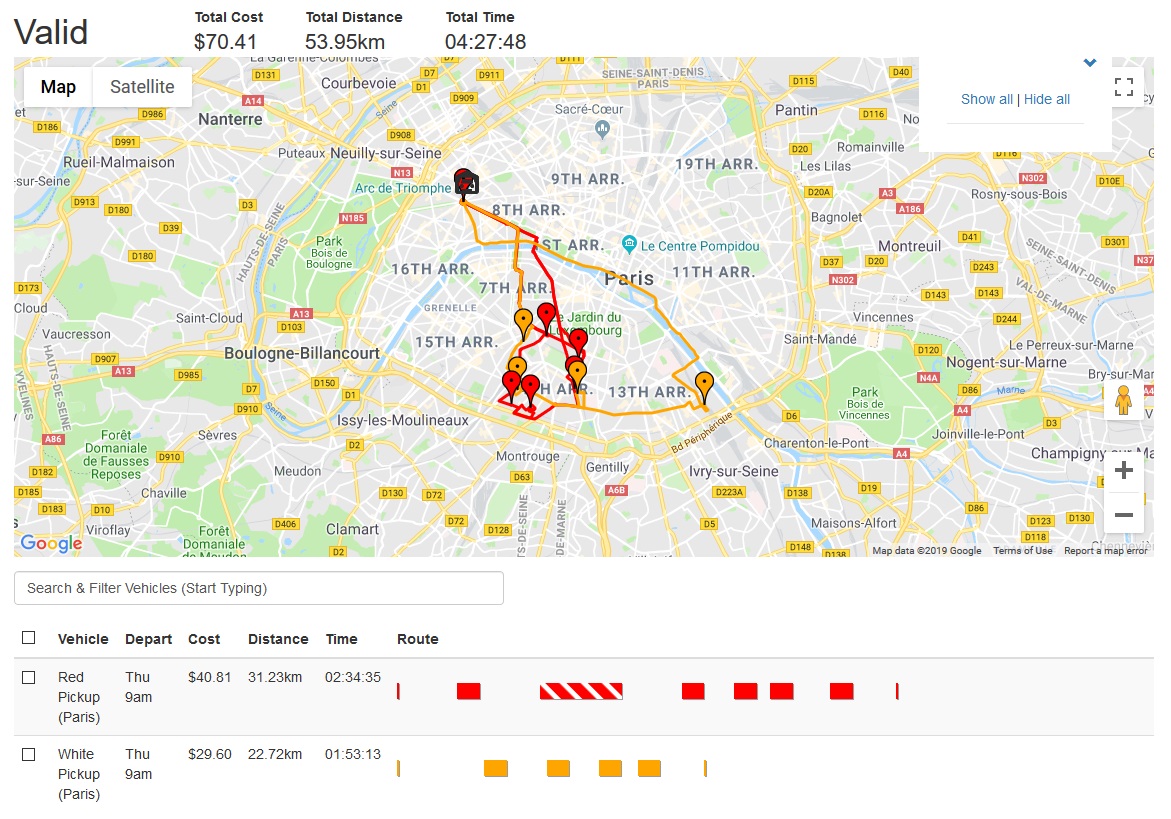

Here's a great example:

In this instance the depot is positioned West, South West of the dense center of town. There are also plenty of deliveries that need to be made in outlying areas. In addition the delivery schedule is extremely tight - having only 8 hours of operation.

It would most likely not be possible to accomplish a real-world optimal solution like this with artificial algorithmic shortcuts imposed on the system. Most likely a shortcut algorithmic solution would still "look good" but would cause some vehicles to violate their operating hours by forcing them into sub-optimal routes.

3. Accurate Vehicle Capacities

It's not an uncommon requirement to pickup something from one location (that's not the depot) and drop it off at another location. Delivery planning software needs to be able to cater for this (otherwise your delivery plan might involve arriving at the drop-off location before picking up the package).

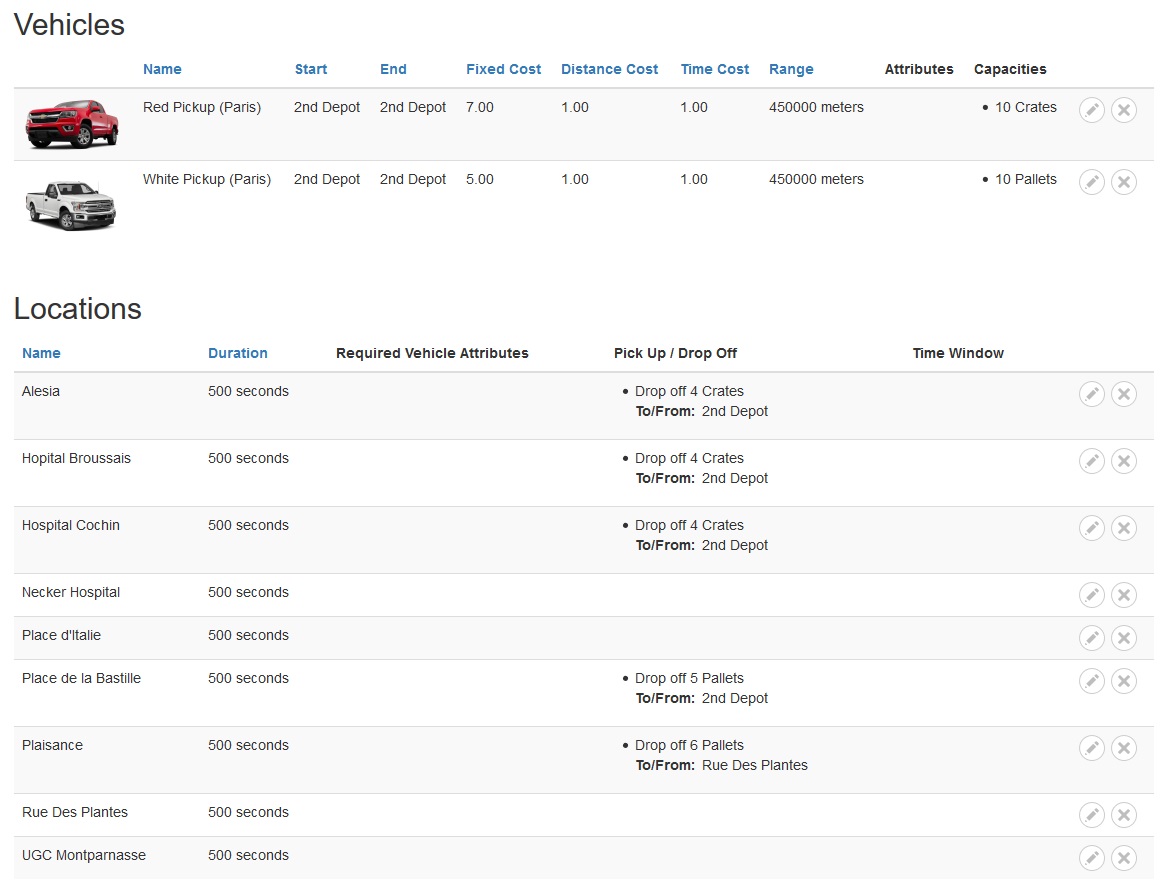

To test this out, let's add a pickup and drop-off of 6 Pallets from one stop to another:

Notice that our White Pickup has capacity for 10 Pallets but we are dropping off 5 Pallets from the depot and 6 Pallets from Rue de Plantes for a total of 11 Pallets. What do you expect will happen?

Here's the result:

This solution might surprise you. After all, the White Pickup only went out once but had to carry 11 Pallets with a capacity to carry only 10. In actual fact, it dropped off the 5 Pallets from the depot before picking up the 6 from Rue de Plantes - all without exceeding its carrying capacity of 10 Pallets.

It accomplished this using a route that is both efficient and well optimized.

The alternative might have been to send the vehicle out to make the inter-location delivery and go back to the depot to pickup the additional 5 Pallets before delivering those. That, of course, would have cost your business more time, fuel and money.

You can also use these optimizations to determine whether or not it is actually possible to meet your delivery commitments at all - given the natural constraints on your business (i.e. number of vehicles available, operating times, carrying capacities, number of deliveries, etc). This is, in itself, extremely useful for companies that might otherwise spend a lot of money growing their fleet instead of utilizing the vehicles they have more efficiently.

4. Flexible Location Constraints

What if you had a situation where a vehicle had to meet multiple criteria in order to successfully fulfil an delivery? For example, it might need to be a cold chain vehicle and have at least 3 drivers (in other words, one driver and two packers).

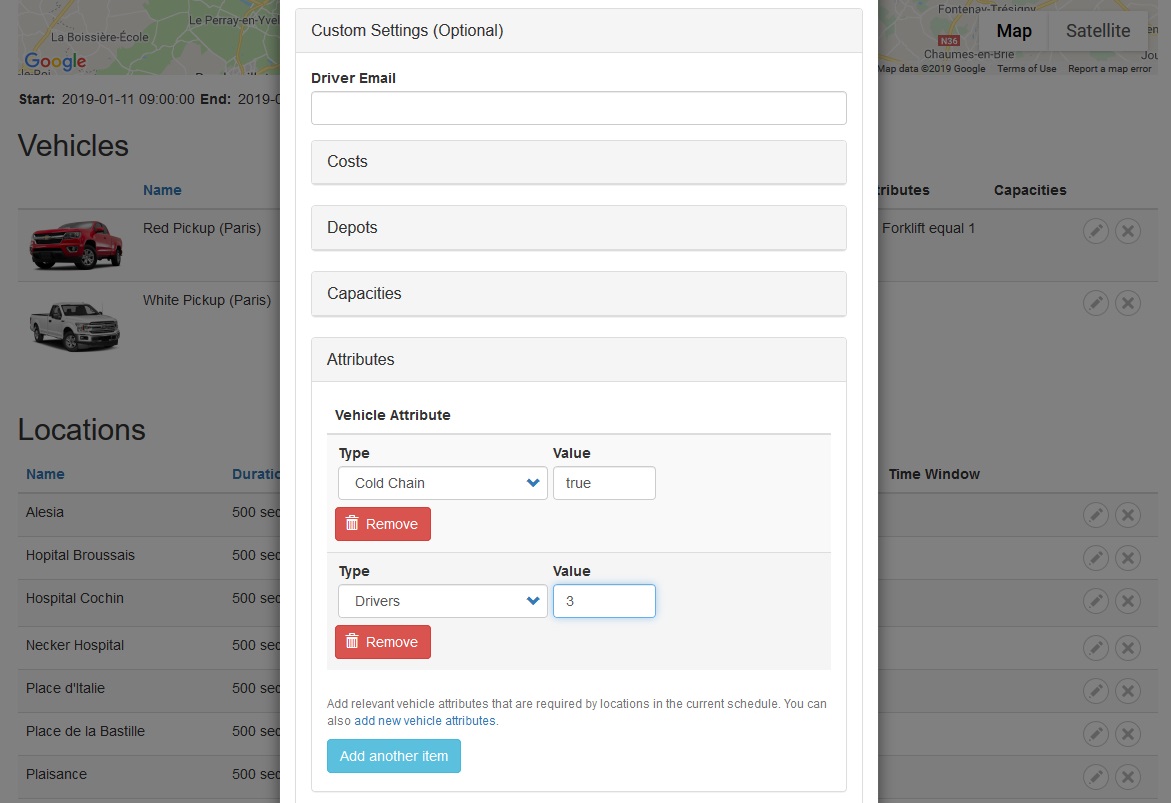

We could specify the following attributes on the White Pickup:

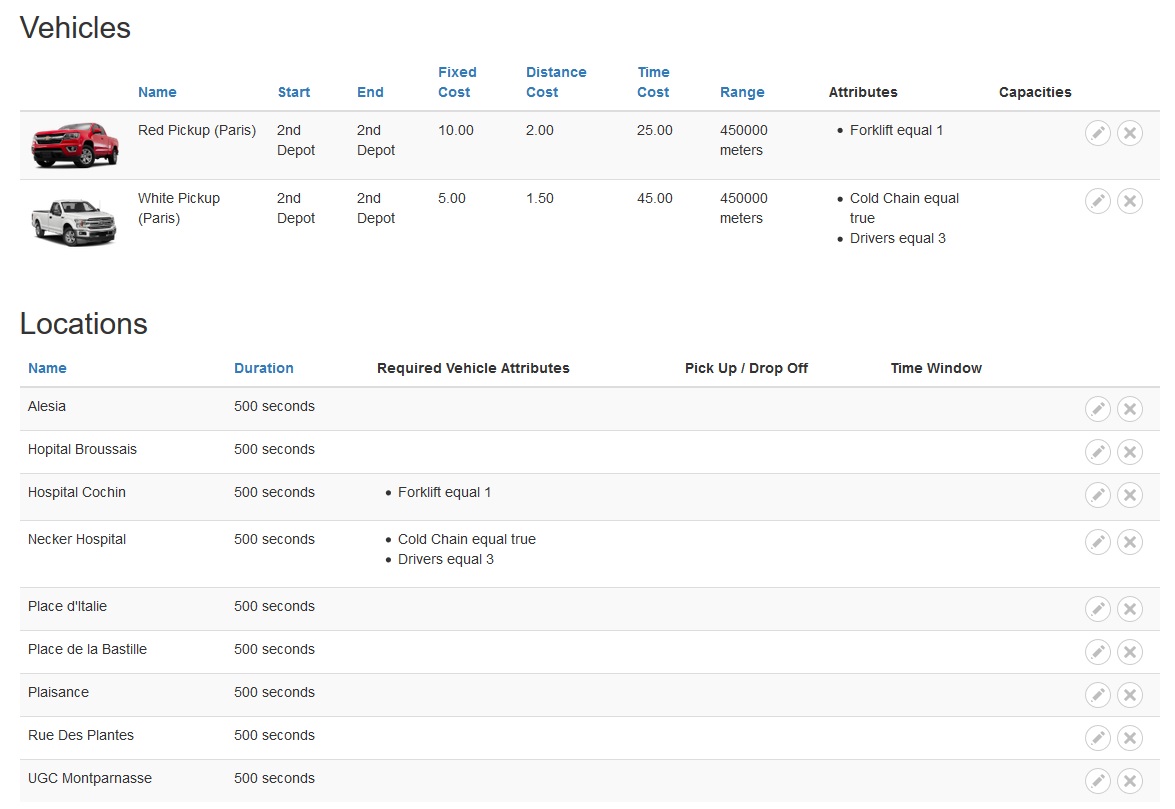

With a vehicle in place that can meet the delivery constraints required for our schedule we can set up a hypothetical schedule like this:

Note that I've updated the costs associated with the White Pickup commensurate with the fact that there are now 3 employees in that vehicle at any one time, and that it has cold chain facilities making it more expensive to run.

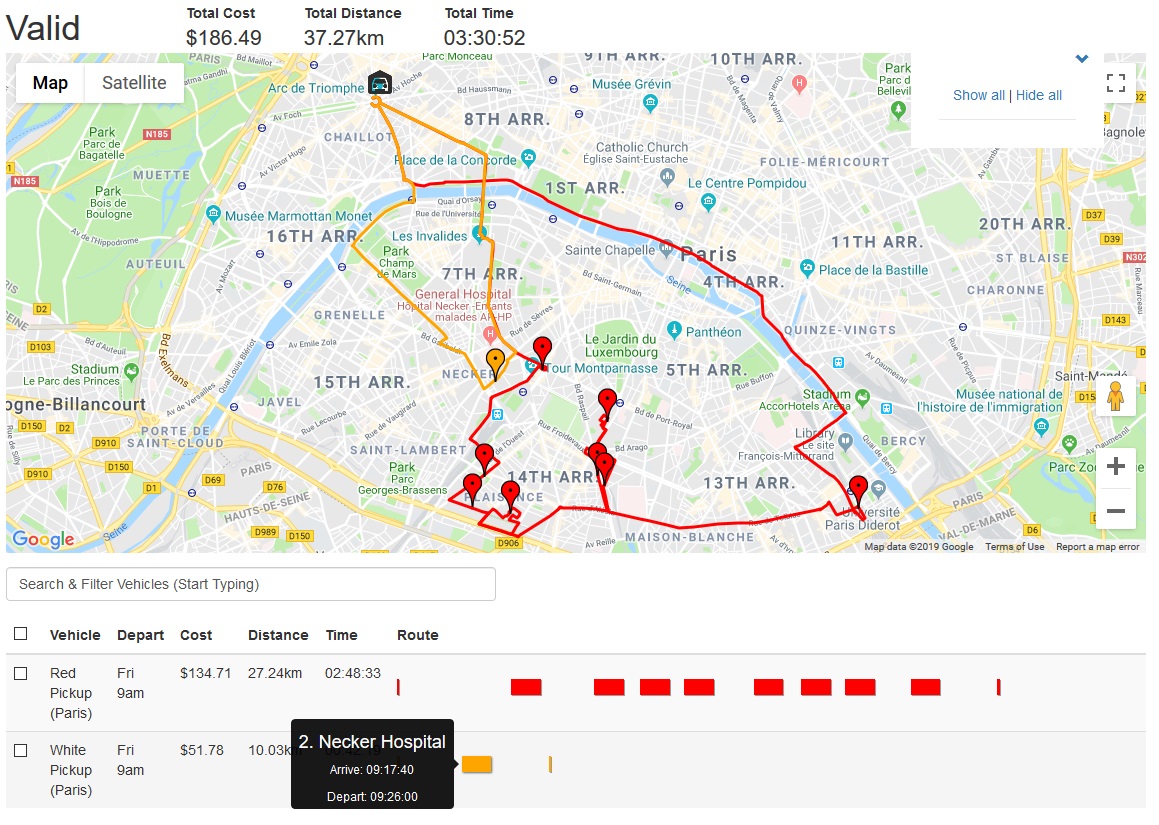

The solution is fairly straightforward:

As you can see, the White Pickup has now visited Necker Hospital that required 3 drivers and a cold chain vehicle. However, because the White Pickup is now more expensive to run (because of the hourly wage bill associated with 3 employees) it only visits one location before returning to the depot.

5. Shareable Delivery Plans

Generating an optimal delivery schedule is one thing. Getting that information to the relevant role-players is pretty important too.

Obviously making use of a delivery planning API means solutions can be integrated directly into your existing systems as you see fit. But what about online route optimizations?

In general, you need facilities to print, export (via JSON or XML for easy integration with your existing infrastructure) and share relevant parts of the solution with everyone from the warehouse/depot manager to the drivers.

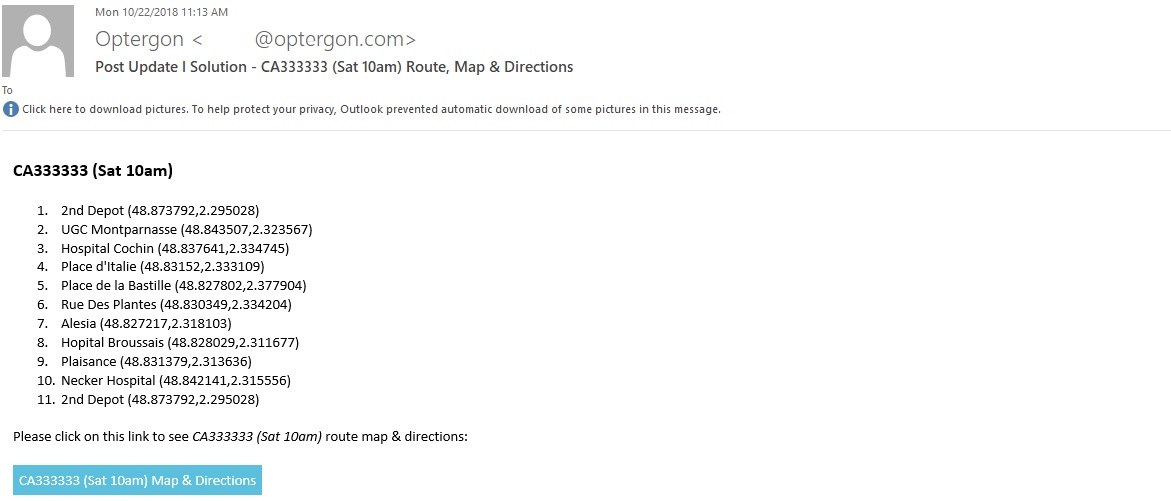

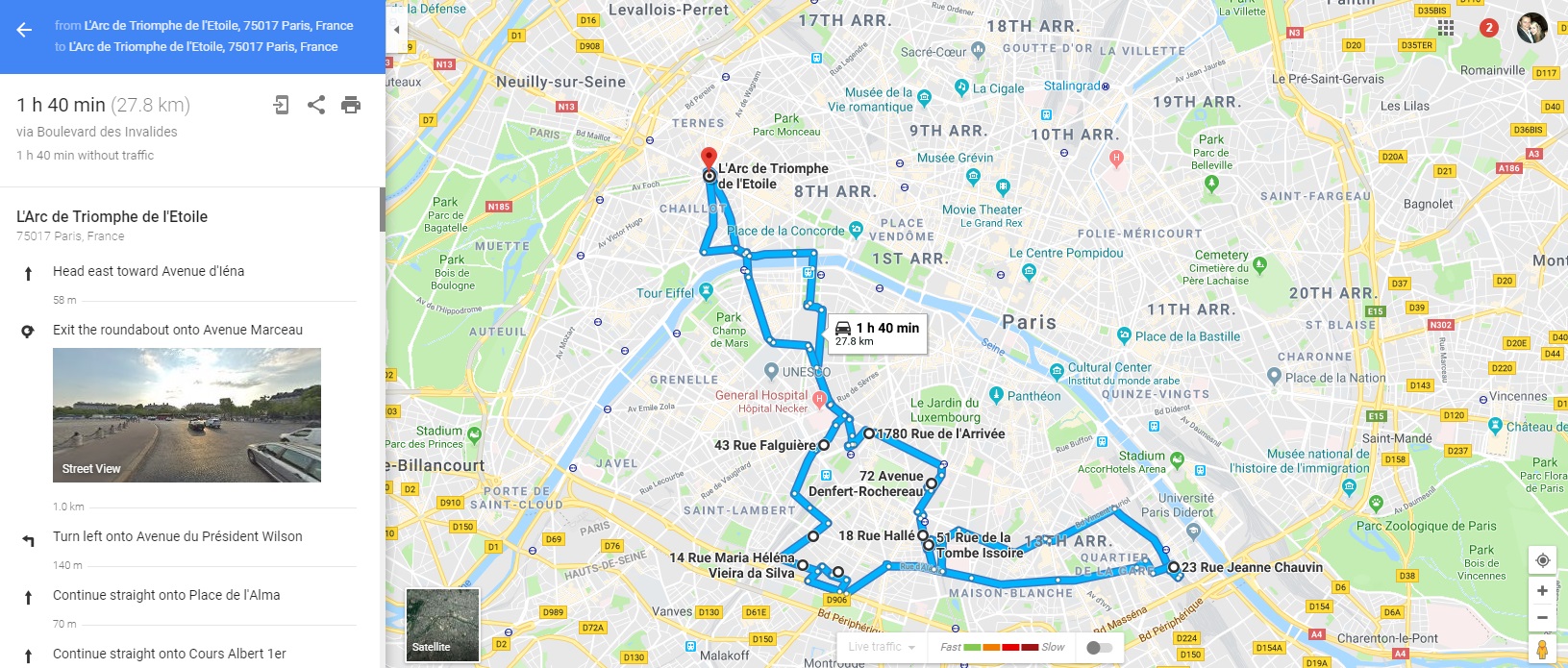

For example, it should be possible to email a complete route map directly to the driver(s) of any vehicle used.

Potentially that email could contain an ordered list of stops (with GPS points), departure time, links to a live map, etc.

A route map and directions can also provide turn-by-turn information, as well as pictures and times with live traffic data that could be shared to the driver's mobile at the click of a button.

The same might go for a packing manifest sent to the warehouse so the depot manager knows how to pack each vehicle and the order in which to pack deliveries, ahead of time.

So those are five of the most important features to look out for when choosing a delivery route planning system for your business. You can get one month free delivery route planning on Optergon to try out all these great features and start lowering your costs and improving efficiency today. Alternatively, take a look at our route optimization API for a simple, fast way to integrate powerful delivery planning features into your business.